OxyPro

|

Certain models of the OxyPro have been tested and are listed under NSF/ANSI Standard 40 and are hereby certified as Class I Aerobic Wastewater Treatment Plants. |

The

OxyPro 1000 is an innovative wastewater treatment unit designed

to handle flows up to 500 gallons per day. It combines the

best design components of modern aeration methods and avoids

unnecessary complexity in both installation and operation.

The OxyPro is suitable for installation in new septic systems

as well as an addition to existing systems in order to increase

the capacity of the disposal area.

There

are several advantages to using the OxyPro Wastewater Treatment

system:

- Extending

the life of a disposal area.

- Reducing

the required size of the disposal area.

- Removal

of nitrates in the wastewater.

- Reduced

risk of environmental pollution.

OxyPro

is designed with the owner in mind. All outside components

are buried out of sight, and the control and blower enclosures

may be mounted inside in a storage or utility space. OxyPro

is quiet, inexpensive to operate, and requires little maintenance.

Each unit is constructed using the highest quality materials

and methods to ensure reliability and longevity. Aeration

Systems, LLC warrantees each unit for an initial two-year

period and offers a variety of extended service contracts.

The

OxyPro Wastewater Treatment system is available in a variety

of models:

- The

Oxypro comes standard in a concrete tank for ease of

installation on most sites, but is also available

in plastic tanks for difficult sites where access is

limited.

- The

OxyPro is available with a gravity or pumped outlet,

depending on the site requirements.

- The

Oxypro can be supplied with all of the headworks necessary

to be used with a pressurized drip irrigation disposal

system.

- Where

disinfection of the wastewater is required prior to

disposal, a sterilizing ultraviolet unit is available.

For people seeking a quality cost-effective solution to wastewater

treatment, OxyPro is the best choice.

The Process

Septic Tank:

Wastewater from the house flows into a septic tank sized

according to State Code. In the septic tank, settling occurs

with the formation of sludge and scum. This material is

removed periodically by a pump truck. Clarified wastewater

flows through a filter and into the OxyPro tank.

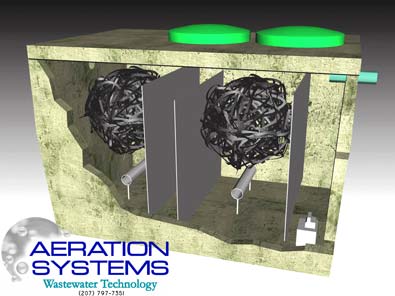

Aeration Treatment Unit:

The

first (inlet) compartment of the OxyPro tank is the aeration compartment.

Air is pumped under pressure from an efficient, linear-diaphragm

pump through flexible-membrane bubble diffusers anchored to the

bottom of the tank. This creates a number of curtains of

tiny air bubbles, which allow for excellent oxygen transfer efficiency.

Through this process of aeration, an aerobic environment is established

in which oxygen-loving microorganisms can flourish and digest

the organic material in the wastewater. These microorganisms

grow on a synthetic ribbon media suspended in the water column

and form large colonies, visible to the naked eye. Eventually,

these colonies become too large and heavy, and due to the agitation

caused by aeration, slough off. The sloughed colonies are

carried by the wastewater into the next compartment.

The

second compartment is designed as an upflow clarifier. This

means that the wastewater is given a calm environment where it

flows slowly upward to the outlet. The quiescent environment

allows the sloughed colonies and other suspended particles to

settle to the bottom of the clarifier. A submersible pump

periodically pumps the accumulated sludge from the bottom of the

clarifier to the septic tank, where it is ultimately removed when

the septic tank is serviced. The return of this water to

the anaerobic carbon-rich environment of the septic tank also

serves to enhance denitrification, typically resulting in a 50%

reduction of total nitrogen. The cleaned and clarified effluent

from the OxyPro flows out of the treatment module and on to a

subsurface disposal area.

The

operation of the OxyPro is fully automated and controlled by a

programmed computer module. This control panel operates

the pumps and blower, and is equipped to detect a mechanical failure

of the blower, as well as unusual water levels in the tank.

In the event of such a problem, the panel is equipped with both

audio and visual alarms to alert the owner. Remote alarms

are also available to alert Aeration Systems representatives directly.

Technical Information